Simulation and experiment on cutting reinforced concrete with jet combined shield method

-

摘要: 针对传统盾构刀具直接切削钢筋混凝土所产生的弊端,进行磨料水射流联合盾构刀具切削钢筋混凝土研究。通过仿真和试验探究了磨料水射流在不同横移速度下对钢筋和素混凝土的切削效果和切割机理并确定了切割钢筋混凝土的最佳横移速度。研究结果表明:磨料水射流对钢筋和混凝土的切割机理存在差异性,水射粒子对钢筋的切割贡献十分有限;混凝土的切口深度和宽度大于钢筋,对横移速度变化的敏感性小于钢筋;在高横移速度下混凝土切口损伤宽度得到扩大但并不显著、钢筋出现切割残余;切割深度随着横移速度的增加而减小,下降速度由陡变缓;10 mm/min的横移速度较好满足切割C55钢筋混凝土的要求。基于前期研究成果开展模拟盾构切削试验,分析了磨料水射流联合盾构刀具破除C55钢筋混凝土的效果、刀具损伤和参数特征。试验结果表明:磨料水射流联合盾构刀具切削能有效解决盾构刀具直接切削所产生的钢筋缠绕问题,减少了刀具损伤,控制了扭矩峰值。Abstract: The research of abrasive water jet combined with shield cutting tools in the cutting of reinforced concrete is carried out because of the disadvantages of the traditional shield cutting tools in the direct cutting of reinforced concrete. The cutting effect and mechanism of abrasive water jet on reinforced concrete and plain concrete under different moving speed are explored, and the best moving speed of cutting reinforced concrete is determined through simulation and experiment. The results show that the cutting mechanism of abrasive water jet is different from that of concrete. The contribution of water jet particles to steel cutting is limited. The depth and width of concrete incision are greater than those of steel. The sensitivity of concrete to the change of transverse velocity is less than that of steel bar. The damage width of concrete notch is enlarged but not obvious, and the cutting residues occur in the reinforcement under high transverse velocity. The cutting depth decreases with the increase of the traverse speed. The descending speed slows down. The transverse velocity of 10 mm/min can meet the requirements of cutting C55 reinforced concrete. The cutting experiment of the simulation shield machine is carried out based on the previous research results. The effect, tool damage and parameter characteristics of the abrasive water jet combined shield machine tool to break C55 reinforced concrete are analyzed, and the results are compared with those of the shell knife direct cutting. The results show that the abrasive water jet combined with shield cutter cutting can effectively solve the problem of steel winding caused by the direct cutting of shield cutter, reduce the cutter damage and control the peak torque.

-

Keywords:

- tunnel excavation /

- abrasive water jet /

- shield cutter /

- reinforced concrete /

- simulation

-

0. 引言

随着地下工程的发展,盾构隧道广泛用于城市地铁建设中,但在城市建筑密集区无法避免的会正面遭遇钢筋混凝土桩基等障碍物,若采用传统方法破除[1]势必会增加工期、扩大成本和扰动周边环境。针对传统方法的弊端,国内在盾构直接切桩技术上实现了突破,成功完成深圳地铁9号线[2]、上海地铁7号线和10号线[3]区段桩基的直接切削。袁大军等[4-5]依拖苏州地铁2号线从理论、模拟和试验的角度深入分析了切桩效果和刀具损伤,发现改进后的盾构机能够满足同时切削两根桩基的要求但是刀具合金损坏和钢筋缠绕刀盘现象严重。综合国内目前破除桩基的方法,主要手段还是依靠隧道掘进机的直接切削,对钢筋的切断显得极其困难,破拆效率低下,刀具的磨耗、崩断以及钢筋缠绕刀盘等问题尤为突出,在迫不得已的情况下,还需开仓进行人工处理,这些问题都给工程施工带来了极大的困难和安全隐患。

磨料水射流作为一种液固两相射流,是由高压水射流混合磨料颗粒形成,因其具有较大的能量而广泛运用于工业切割技术中[6]。若将其与盾构刀具结合,采用磨料水射流对钢筋混凝土桩初次切割,再利用盾构刀具进行二次切割将有效减少盾构刀具直接切削所带来的一系列问题。在20世纪70年代,Hood[7]将纯水射流竖直布置在刀具的前沿并紧靠刀具切割面进行切割岩石试验,发现可以显著降低前头钻头受力大小。从20世纪末至今,日本对水射流联合盾构刀具破除钢筋混凝土预制桩、木桩、H型钢等障碍物的技术研究日趋完备[8],但公开的技术成果却十分有限,无法对其进行直接借鉴。

国内对于磨料水射流联合刀具破除障碍物的研究尚不完备但仍有不少学者作出了探索。卢义玉等[9-10]分析了纯水射流辅助刀具破岩机理并将水射流布置于PDC刀具后方进行切割岩石试验,发现水射流可以有效减少刀具受力30%~50%。张文华等[11]建立了高压水射流-机械齿破岩的数值模型,认为高压射流和机械齿在联合破岩过程中是互相促进的并给出了射流和机械齿最佳间距值为13 mm的建议。曾锐[12]提出了一种新型的滚筒式采煤机-高压水射流截割系统,能实现对坚硬煤层较好的切割且降低了切割扭矩。陈跃强[13]联合磨料水射流和截齿对岩石进行切割,磨料水射流的加入能有效的降低截齿破损和断裂概率并提高了破岩效率。但以上研究的破除对象主要是岩石和煤层,且多以对纯水射流联合刀具破除障碍物为主。目前对于钢材或混凝土等其他材料的破除研究主要基于磨料水射流单独切割。杨清文等[14]、王伟[15]、赵宏伟[16]通过对混凝土、钢板、碳纤维复合材料和微晶复合材料进行切割试验探究了靶距、压力和流量等相关参数对切割性能的影响。

本次研究充分考虑钢筋混凝土中混凝土和钢筋两种主要材料切割性能的差异性,通过仿真和试验确定切割钢筋混凝土的最佳横移速度并在此横移速度的基础上进行模拟盾构试验,验证磨料水射流联合盾构刀具破除钢筋混凝土的效果,为实际切割钢筋混凝土桩基工程提供借鉴。

1. 磨料水射流切削仿真

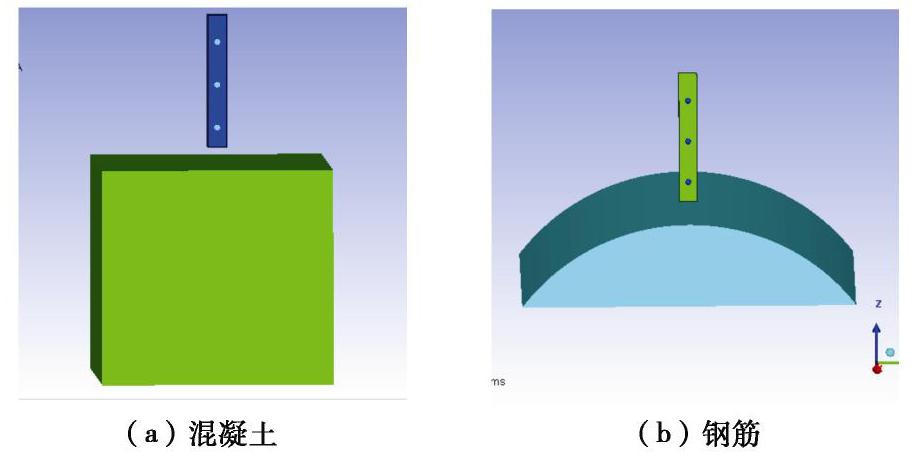

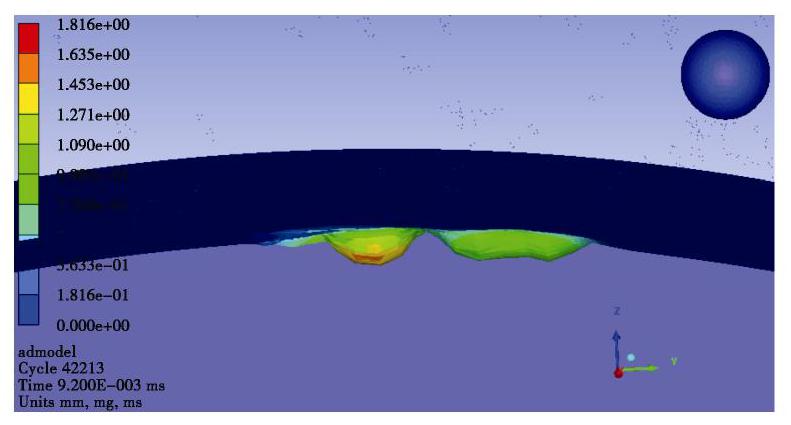

借助Autodyn显式分析软件建立切削钢筋和素混凝土模型,并采用SPH-FEM耦合的方法进行磨料水射流切削模拟,研究磨料水射流在不同横移速度下对钢筋和素混凝土的切削效果和切割机理并为后续试验中横移速度的选择提供初步指导。

1.1 磨料水射流建模

水射流采用SPH粒子建模(粒子个数为11641),靶板和磨料粒子采用有限元建模。射流尺寸依据实际管嘴尺寸(0.33 mm)建为0.33 mm×0.33 mm×3 mm块体;混凝土尺寸为5 mm×5 mm×5 mm块体,采用RHT本构模型,模型关键参数见表1;钢筋尺寸采用Φ10 mm圆柱上部1/4,采用Johnson-Cook模型[17],模型关键参数见表2;磨料粒子设置为刚体,密度为2.64 g/cm3并按照实际粒子尺寸(直径0.15~0.3 mm)建为Φ0.2 mm球体,磨料浓度为5%,其他相关材料力学参数见表3。

表 1 RHT模型关键参数Table 1. Key parameters of RHT model本构模型参数 失效参数 A N Q0 BQ D1 D2 1.6 0.61 0.1 0.6805 0.0105 0.04 1 表 3 材料的力学参数Table 3. Mechanical parameters of materials类别 弹性模量/GPa 泊松比 密度/(g·cm-3) 混凝土 35.5 0.2 2.75 钢筋 200 0.25 7.89 依据Bernoulli法则[18],将实际压力320 MPa换算为800 m/s的射流速度。建立简化仿真模型如图1,忽略磨料粒子喷出后的轨迹变化。

因受建模和求解时间限制,在此模型下若按照实际速度将无法体现出明显的差异性,因此将两颗磨料粒子落下的横向位移差大到不发生接触定义为高横移速度,两颗磨料粒子落下出现横向位移差但仍有接触定义为低横移速度。

1.2 仿真结果分析

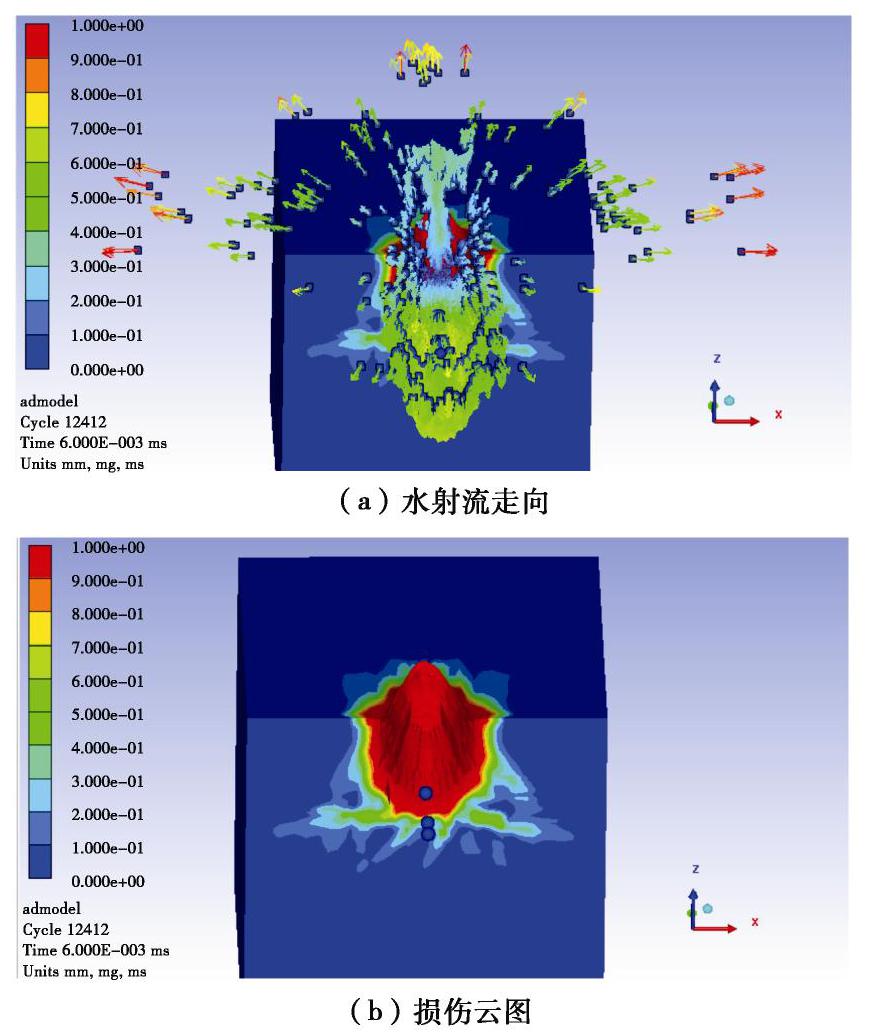

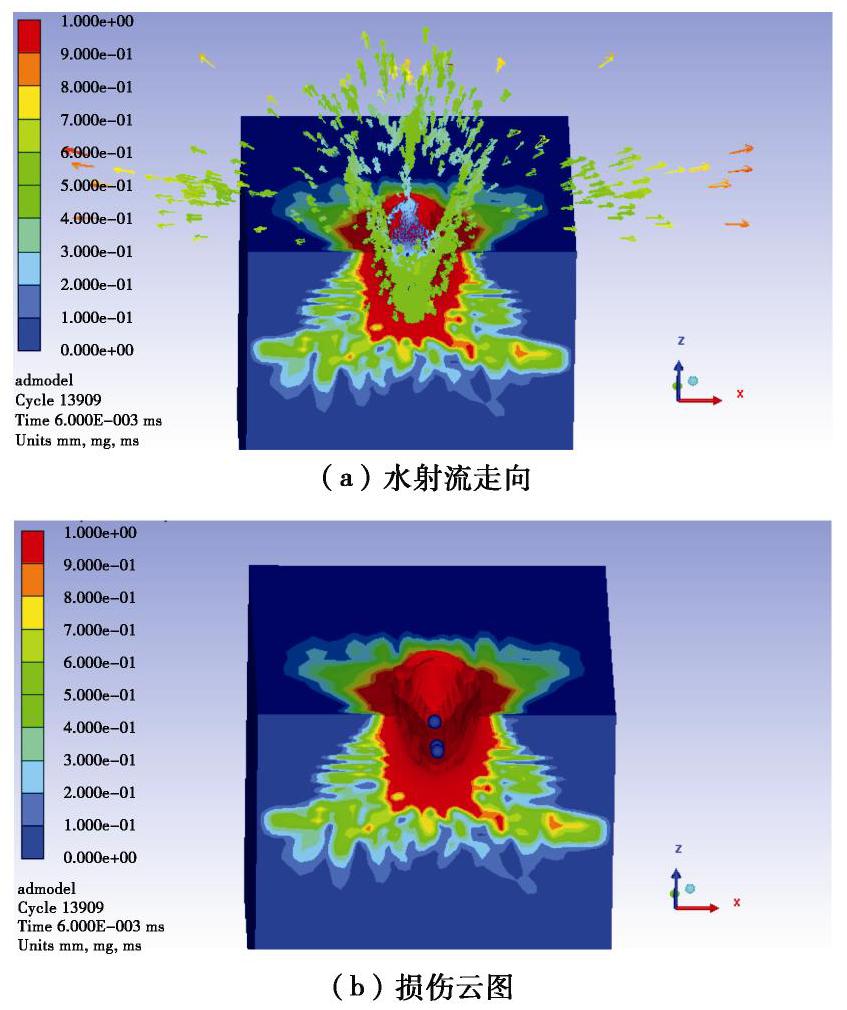

由图2和图3可以看出,纯水射流在切割混凝土中占据重要一环,在不同横移速度下,最外侧混凝土均能被水射粒子剥落,损伤口呈现“U”型且“U”型口上两端出现向两边扩散情况,这是受完成初始侵彻水射粒子反弹冲击的结果。此类完成初始侵彻的水射粒子按照后续工作情况可以分为3类:

(1)水射粒子由边口完全退出工作。

(2)部分粒子经由反弹后冲击混凝土前端,率先对混凝土进行横向预切割。

(3)部分粒子反弹后冲击混凝土左右宽度壁端,造成切割上端口的进一步增大。在不同横移速度下以上3种情况所占比重呈现明显差异性,在低横移速度下,水流裹磨料粒子直接从边口流出占据很大比例,而在高横移速度下,撞击前头和四周的水射粒子比例和范围增加且失去初始动能的磨料粒子在混凝土内继续作用的时间变长,水射粒子在撞击磨料粒子后轨迹出现了较大的改变,这些都致使其损伤范围在切深方向和前进方向上都出现了扩大。从切深数据上来看,高横移速度导致了切深的下降。

在模拟切割钢筋时,单独作用于钢筋的纯水射粒子对于钢筋切深的贡献只是产生了部分水射粒子小坑,并没有明显增加切割长度和宽度,这表明切割主要能量来源是磨料粒子并且由于缺少了水射流的辅助,切口宽度也并未出现明显向两边扩展。在低横移速度下时,只有当磨料粒子能量累积才出现了明显的塑性应变的增长,当磨料粒子之间撞击后发生轨迹改变落于初始孔坑附近(图4)形成二次作用,这是钢筋切口宽度增加的重要原因。但在高横移速度下时,能量粒子得不到堆积,出现了明显的“山峰状”切割残余(图5),造成切割无法连续,切割钢筋的横移速度越快,切割残余的范围就越大,将无法有效完成钢筋切割。类比混凝土可以看出钢筋缺少了水射粒子的辅助侵蚀,切割宽度和深度明显小于混凝土同时因横移速度提高造成造成钢筋切割深度下降率(54%)大于混凝土(37%)。

从仿真现象来看,必须采用较低的横移速度才能达到切断钢筋的目的,而破除混凝土需依据实际工程对于破除深度和破除范围的要求而定。

2. 试样试验

仿真因受求解时间限制目前只能在切割现象、工作机理以及大范围横移速度选择上提供一定的指导,无法给出与实际相匹配的横移速度和切深对应关系。因此必须通过实验来得到具体的切深数据。

2.1 试验装置

试验装置采用大地水刀切割设备(图6),可进行三轴切割控制,同时匹配了C50T超高压系统和DAADS自动供砂系统,其中超高压系统采用三相异步电机和手动变量柱塞泵的组合作为其的动力单元,最大工作压力可达380 MPa;DAADS自动供砂系统为水切割机床提供了储砂、供砂功能。

2.2 试验材料

试样在浇筑上考虑两点:①在混凝土强度方面,依据地下连续墙、地下桩基在后期的强度发展,选用了强度为C55,抗渗等级为P12的混凝土。②在配筋方面,参考800 mm厚地下连续墙的典型配筋,主筋选用Φ28与Φ32的HRB400钢筋并筋且将箍筋、主筋间距、箍筋间距都设计为与其一致。基于以上,选用C55素混凝土块(尺寸为500 mm×500 mm×300 mm);Φ28和Φ32点焊并行钢筋;C55钢筋混凝土块(尺寸为500 mm×500 mm×300 mm)作为试验试样。其他相关试验参数见表4。

表 4 试验参数Table 4. Experimental parameters喷嘴材料 最大流量/(L·min-1) 磨料直径/mm 粒子占比/% 蓝宝石 3.7 0.15~0.3 5 喷嘴直径/mm 靶距/mm 射流角度/(°) 射流速度/(m·s-1) 0.33 20 90 800 2.3 试验方案

为提高试验效率,依据模拟分析,单独切割钢筋时采用低速切割,设定横移速度为20~200 mm/min,每20 mm/min为一个试验工况并增补横移速度为2,5,10 mm/min的3组工况。单独切割素混凝土时采用高速切割设定横移速度为500~2000 mm/min,每500 mm/min为一个试验工况并增补横移速度为100,200 mm/min的2组工况。通过分析不同横移速度下的切割效果为钢筋混凝土切割速度的选择提供依据,使得在该横移速度下既能破除50 mm厚的混凝土保护层又能对内部钢筋进行较好的切割。

在混凝土试块上共计标注24个测量点、钢筋上标注5个测量点,取测点平均值作为切深数据。

2.4 试验结果分析

(1)钢筋和素混凝土

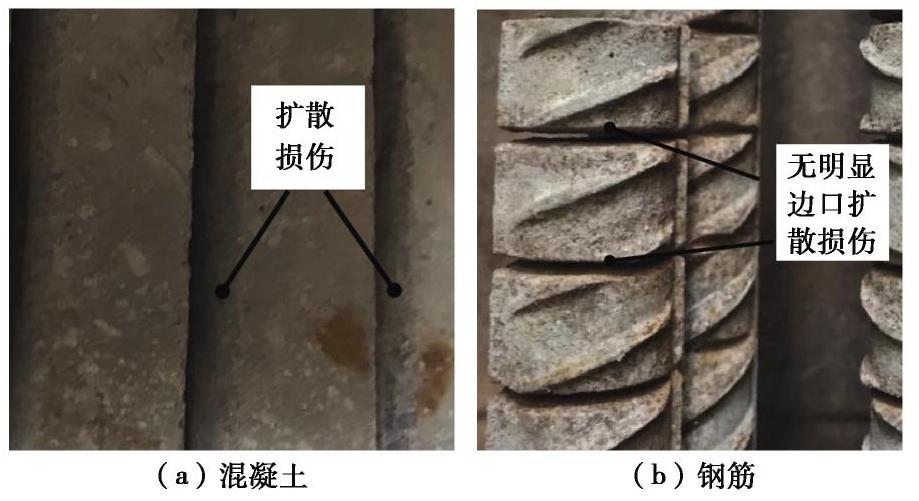

对比观测混凝土和钢筋的切割口损伤,如图7所示,混凝土损伤口上两端出现了与仿真类似的朝两边扩散现象,而钢筋未出现明显的损伤外扩现象。

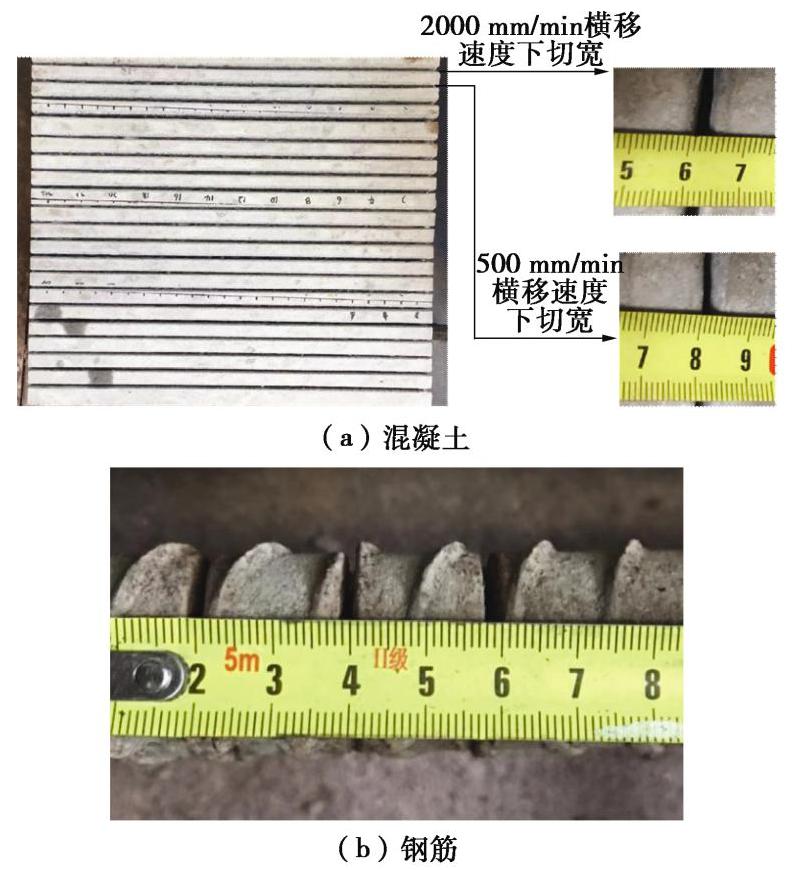

图8为混凝土和钢筋的切口宽度测量,分别对2000 mm/min和500 mm/min横移速度下,混凝土的切口宽度进行测量,2000 mm/min横移速度下损伤口宽度约为6.5 mm,500 mm/min下约为4.5 mm,在较高横移速度(2000 mm/min)下损伤出现了扩大,这进一步证明了当横移速度增加时,混凝土的损伤范围会增加,但是损伤扩大程度相比试块尺寸来说显得微乎其微。同时,对钢筋的切口宽度进行测量,钢筋的切口宽度普遍为2 mm,小于混凝土切口宽度。以上试验切割现象均与仿真现象高度吻合。

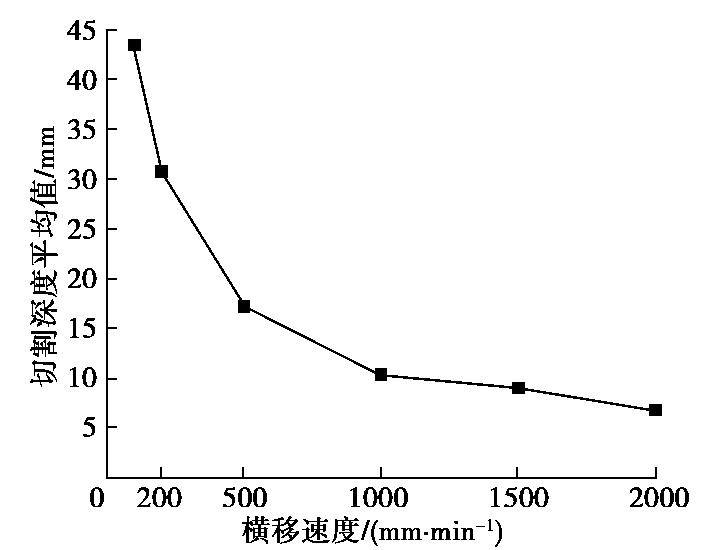

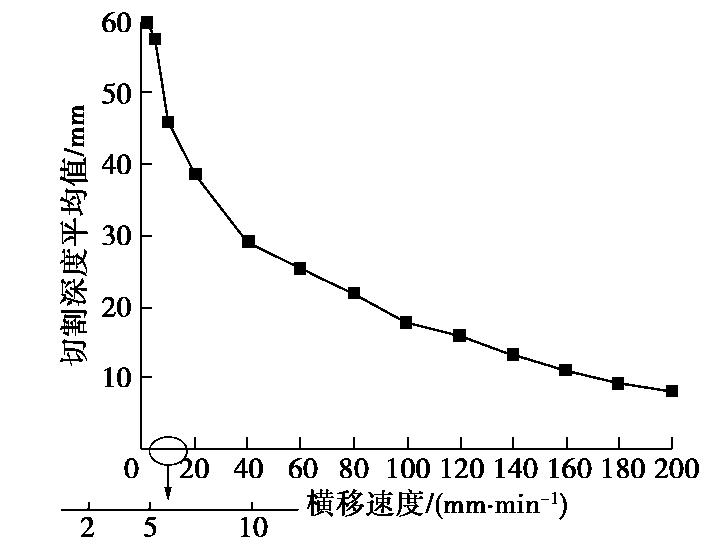

从图9,10可以看出,在100 mm/min低速下的素混凝土切深接近45 mm,按照趋势发展在100 mm/min速度以下横移速度能满足破除50 mm厚保护层的要求。在40 mm/min速度下可以基本完成并筋一半厚度的切深(即单根钢筋)但残留的钢筋由于仍是完整个体仍有出现缠绕的风险,因此必须将控制在10 mm/min以下(切深45.9 mm),才能保证完成主筋3/4的有效切割深度。

随着速度的提升,切割深度不断下降,钢筋在100~200 mm/min速度区间内下降率为55%,混凝土下降率为29.5%,这是因为当横移速度增加时,在同一点打击时间变短致使射流能量分散又由于纯水射流对混凝土的切割和缝隙渗透能较好的弥补磨料粒子能量的分散,导致混凝土的切深下降率低于钢筋。

在切深下降的过程中,下降速度由陡变缓,从能量堆积的角度来看,当横移速度较慢时磨料粒子和水射粒子处于高度集中状态,当横移速度增加时,便可造成大量粒子堆积能量的丧失而当横移速度较快时,大量粒子已经处于分散状态,因增加横移速度导致丧失堆积能量的粒子数目大大减小从而导致切深下降减缓;从仿真中水射粒子的走向来看,横移速度较大时,水射粒子不容易从边口排除,水射粒子囤积在切口内部,造成“水垫效应”,“水垫效应”的存在减小了横移速度对于切深的影响。

(2)钢筋混凝土

在前期仿真和试验的指导下,兼顾考虑单一材料切深数据和切割时长,选用10 mm/min作为钢筋混凝土的切割横移速度,在此横移速度下能满足切割钢筋和破除50 mm混凝土保护层的要求。

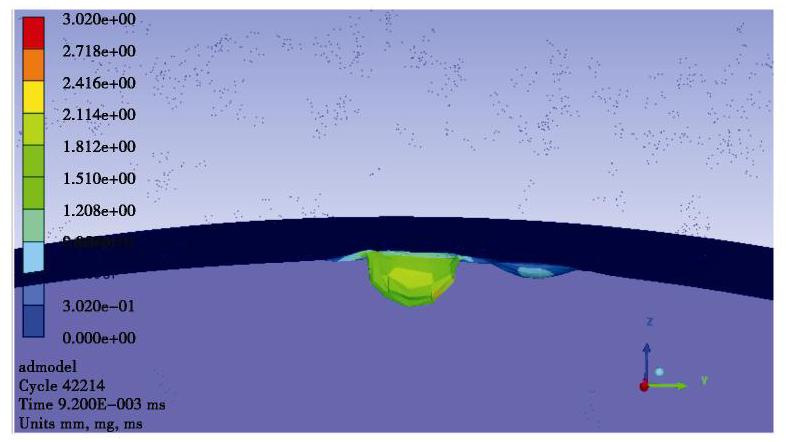

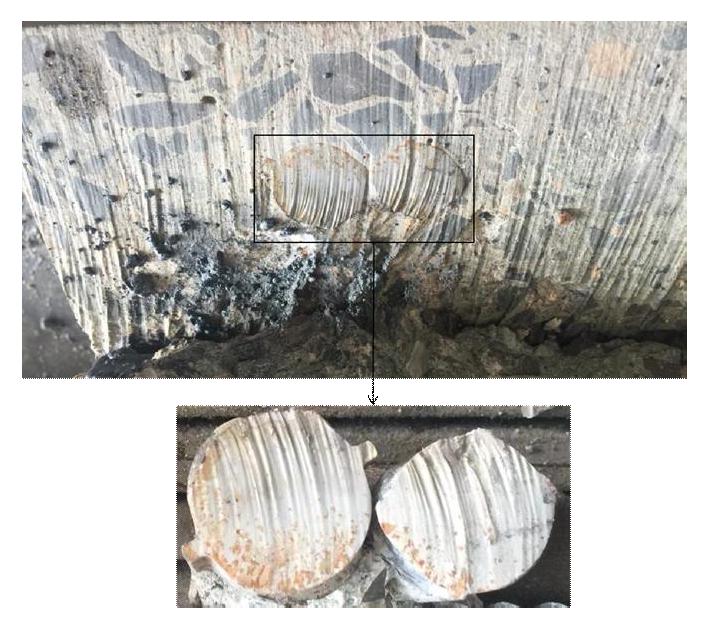

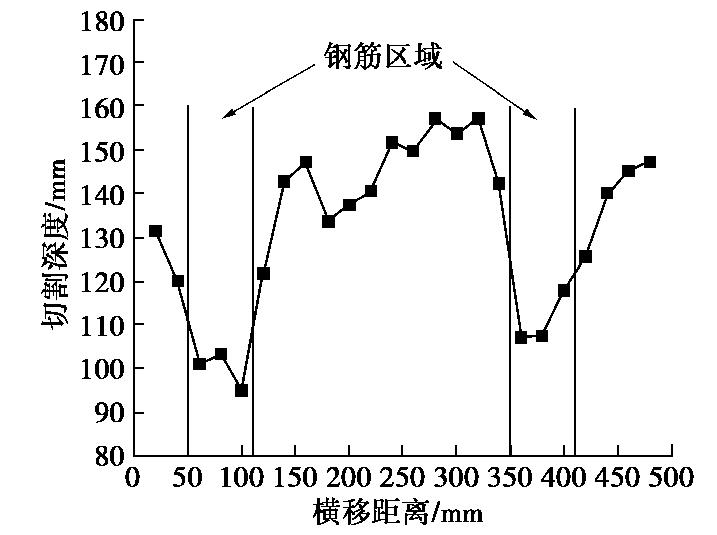

图11为凿除外部混凝土的内部切割迹象图,图中显示钢筋混凝土内部出现大量波浪条纹状切割纹和“J”型不规则尖端。波浪条纹类与仿真中切割钢筋时产生的切割残余存在一定的相似性,由于纯水射流对于较硬材料的切割能力十分有限,必须在磨料粒子作用的基础上才能进一步增加较硬材料的切割深度和宽度,但为保证磨料粒子对喷嘴的低磨损率,磨料浓度普遍均不高。因此当水射流横移时,势必会存在纯水射流单独作用区,造成切割残余从而形成这种波浪切割纹同时也造成了波浪条纹在钢筋和较硬的粗骨料中显得更为明显。随着切深的增加,占比重较大的水射流能量会随之减小,同时磨料粒子在底部存在一个反弹区域能造成多次切割,这让在深层区的波浪纹比浅层区的波浪纹更为显著。“J”型不规则尖端是由失去动能沉积在切割底部磨料粒子持续受横移作用,强行在底部磨蚀形成。

各测点切深如图12所示,切割过程中出现了较低的切深值,这是由于切割至内部钢筋所致,此类切割现象直观地体现了混凝土和钢筋在切割性能上的差异且在非钢筋区因存在不均匀骨料导致切深数据出现波动。在钢筋区和非钢筋区形成了深度的跃变,在这个基础上受到盾构刀具作用后极可能会出现钢筋黏结着混凝土被剥落的情况。钢筋核心切深为95~105 mm,略大于预期计算值95.9 mm(单独切割钢筋切深和保护层厚度之和),综合切割效果和切深数据,10 mm/min的横移速度能较好的切割钢筋混凝土。

3. 模拟盾构试验

3.1 试验装置

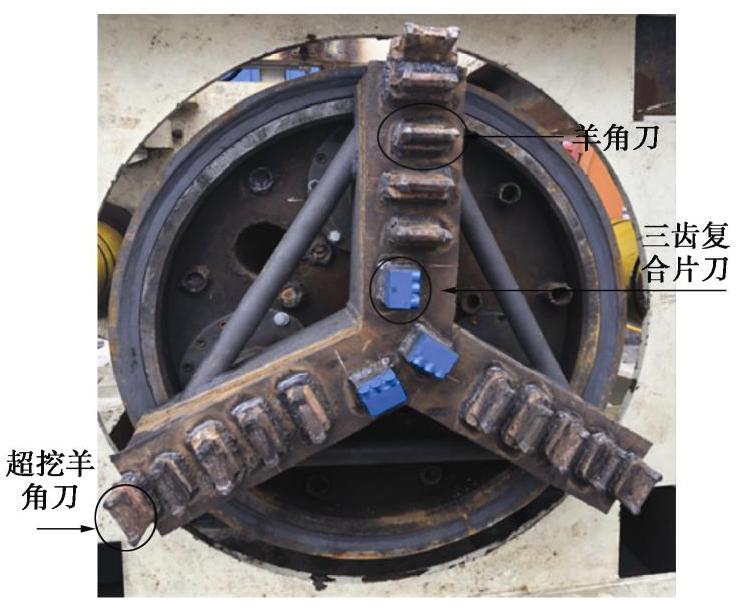

采用Φ1000的小型盾构机(图13)进行模拟盾构试验,盾构刀盘图如图14,依据前期试验成果,采用10 mm/min的横移速度对1000 mm×1000 mm×300 mm的C55钢筋混凝土块体进行切割处理,切割处理后的混凝土块如图15所示,随后采用盾构刀具对钢筋混凝土块进行直接切削。

3.2 试验结果分析

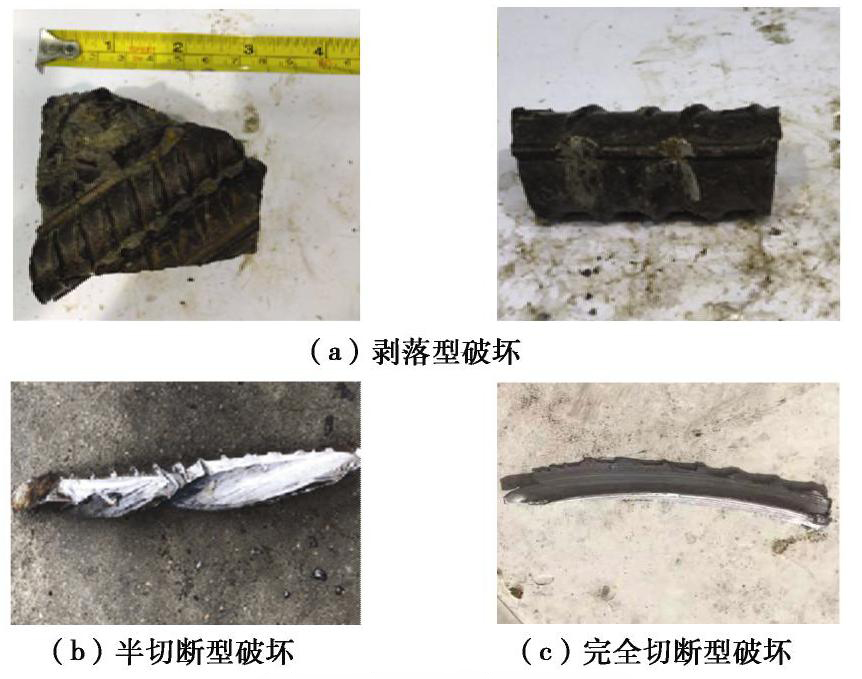

在钢筋混凝土切割试验中,钢筋的破坏形式是主要研究对象,破坏形式见图16,可以分为3种:

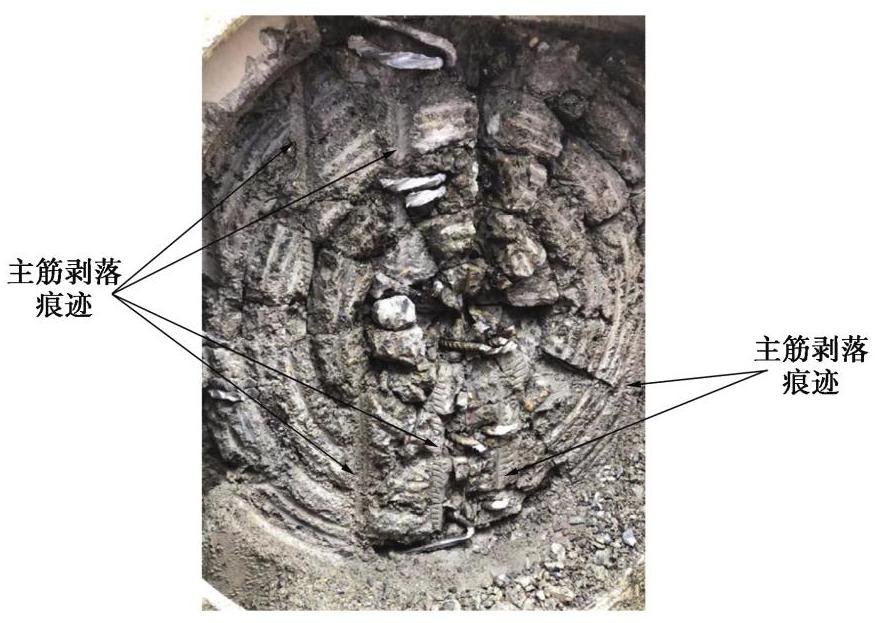

(1)剥落型破坏,在切削了包裹在其外层的混凝土后,钢筋直接被剥落或连带着混凝土被整体剥落。产生原因是钢筋在试块内部两端都被磨料水射流切断或一端被磨料水射流切断另一段原为自由端且前文中提及的深度跃变导致出现了钢筋和混凝土混合整体剥落。剥落型破坏是所有被切割钢筋主要破坏形式,主筋、箍筋和定位筋均存在此种破坏形式,其中又以主筋占据比例最高,所有主筋(HRB400级Φ28、Φ32钢筋)甚至双主筋(并筋排布的HRB400级Φ32钢筋)都是以这种方式被切割破坏,在钢筋混凝土切割面可以清晰的看到主筋剥落的痕迹(图17)。

(2)半切断型破坏,盾构刀具将钢筋一端切断继而掉落。产生原因是钢筋只有一端被磨料水射流切断,在模拟盾构切割时,无法直接剥落,需依赖刀盘的反复磨削将其磨断,这种破坏形式主要存在于箍筋切割破坏中。

(3)完全切断型破坏,受盾构反复切割从而直接切断。产生原因是个别钢筋位于水射流切割盲区或水射流对于其切割作用不显著,必须依靠盾构刀具对其直接切削,在钢筋碎屑上会留下十分显著的刀具运动轨迹,此类破坏占比重较小。综合以上分析,钢筋的破坏形态充分体现磨料水射流在切割钢筋混凝土时对盾构刀具辅助效果显著,成功解决了在盾构刀具直接切割钢筋混凝土时钢筋缠绕的难题。

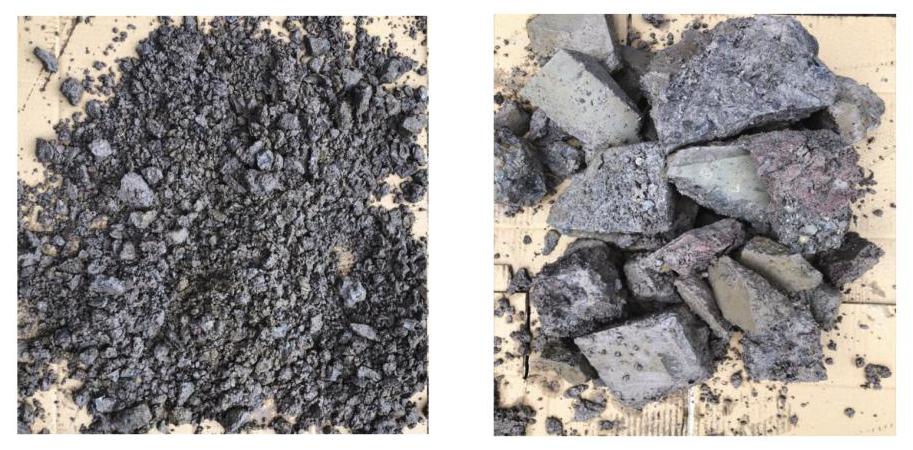

钢筋碎块中,主筋的数量最多,共有37枚碎块,箍筋次之,共有27枚碎块。长度在51 mm至150 mm之间的钢筋碎块在所有不同直径钢筋碎块中占比最大,这主要与盾构刀盘采用每隔100 mm画同心圆的方式来进行切割有关。混凝土的出渣情况如图18所示,左侧为中细粒径渣土,右侧为大粒径混凝土碎块。大粒径的混凝土碎块占总渣土的10%左右,其中最大的混凝土碎块粒径大约为220 mm。

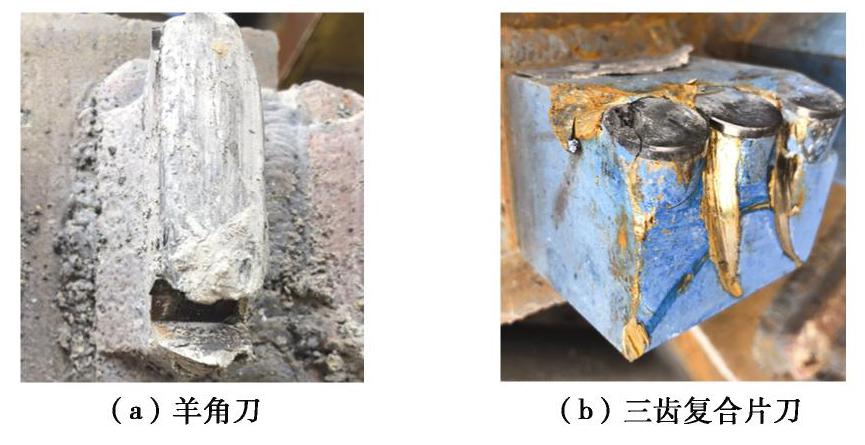

图19为刀具损伤图,损坏率为40%,损伤多产生于合金刀具与钢筋的相互作用。其中羊角刀磨损严重,其损坏形式大部分为刀头小块崩落。刀盘中心处的三齿复合片刀刀头也产生了较为明显的损伤,同时受到混凝土切割盲区的反作用影响,三齿复合片刀刀座磨损严重,但所有刀具仅出现了3处刀具切齿整块崩断且未出现刀具整体崩脱,损伤程度并不严重,这得益于磨料水射流对于钢筋混凝土的前期切割。

从切削数据上分析,模拟盾构机仅切削混凝土表层,推进速度可达18 mm/min左右,后进入平稳切削段时,其推进速度稳固于2~3 mm/min。整个过程推进力最大为26 kN,刀盘的最大扭矩为11 kN·m,约占试验模型机额定扭矩的50%,通过扭矩数据可以看出,在前期磨料水射流的帮助下,可以成功将盾构刀具的切割扭矩控制在模拟盾构机额定扭矩的50%以下。

4. 结论

(1)磨料水射流对钢筋和混凝土的切割机理存在差异性,水射粒子对钢筋的切割贡献十分有限而对混凝土的贡献显著,水射粒子的贡献减小了横移速度变化对混凝土切深的影响,使得混凝土的切口深度和宽度大于钢筋。

(2)切割残余显著存在于钢筋和较硬的粗骨料中,钢筋需采用慢速切割,过快的横移速度会加剧切割残余的范围。

(3)磨料水射流切割深度随着横移速度的增加而减小,下降速度由陡变缓,混凝土切口损伤宽度随之出现扩大但并不显著。

(4)10 mm/min的横移速度在缩短切割时间的基础上能有效的切割C55钢筋混凝土,在钢筋区和非钢筋区形成了深度的跃变,导致在后续刀具作用下形成钢筋和混凝土混合整体剥落状渣土。

(5)磨料射流联合盾构刀具切割C55钢筋混凝土有效解决了刀具直接切割产生的钢筋缠绕问题,减少了刀具损伤,控制扭矩在模拟盾构机额定扭矩的50%以下。

-

表 1 RHT模型关键参数

Table 1 Key parameters of RHT model

本构模型参数 失效参数 A N Q0 BQ D1 D2 1.6 0.61 0.1 0.6805 0.0105 0.04 1 本构模型参数 失效参数 A/MPa B/MPa n C m D1 D2 D3 D4 507 320 0.28 0.064 1.06 0.1 0.76 1.57 -0.84 表 3 材料的力学参数

Table 3 Mechanical parameters of materials

类别 弹性模量/GPa 泊松比 密度/(g·cm-3) 混凝土 35.5 0.2 2.75 钢筋 200 0.25 7.89 表 4 试验参数

Table 4 Experimental parameters

喷嘴材料 最大流量/(L·min-1) 磨料直径/mm 粒子占比/% 蓝宝石 3.7 0.15~0.3 5 喷嘴直径/mm 靶距/mm 射流角度/(°) 射流速度/(m·s-1) 0.33 20 90 800 -

[1] 徐前卫, 朱合华, 马险峰, 等. 地铁盾构隧道穿越桥梁下方群桩基础的托换与除桩技术研究[J]. 岩土工程学报, 2012, 34(7): 1217-1226. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201207008.htm XU Qian-wei, ZHU He-hua, MA Xian-feng, et al. Pile underpinning and removing technology of shield tunnels crossing through group pile foundations of road bridges[J]. Chinese Journal of Geotechnical Engineering, 2012, 34(7): 1217-1226. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201207008.htm

[2] 孙波, 肖龙鸽, 孙正阳, 等. 深圳地铁盾构穿越建筑群及切削桩基施工[J]. 隧道建设, 2015, 35(6): 571-578. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201506021.htm SUN Bo, XIAO Long-ge, SUN Zheng-yang, et al. Shield tunneling and pile cutting construction in Shenzhen metro[J]. Tunnel Construction, 2015, 35(6): 571-578. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201506021.htm

[3] 傅德明. 盾构切削混凝土模拟试验和切削桩基施工技术[J]. 隧道建设, 2014, 34(5): 472-477. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201405020.htm FU De-ming. Model test on concrete cutting directly by shield and pile foundation cutting technology[J]. Tunnel Construction, 2014, 34(5): 472-477. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201405020.htm

[4] 袁大军, 王飞. 盾构切削大直径钢筋混凝土群桩的理论和实践[M]. 北京: 科学出版社, 2017. YUAN Da-jun, WANG Fei. Theory and Practice of Shield Cutting Large Diameter Reinforced Concrete Pile Group[M]. Beijing: Science Press, 2017. (in Chinese)

[5] 王飞, 袁大军, 董朝文, 等. 盾构直接切削大直径钢筋混凝土桩基试验研究[J]. 岩石力学与工程学报, 2013, 32(12): 2566-2574. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201312025.htm WANG Fei, YUAN Da-jun, DONG Chao-wen, et al. Test study of shiedcutting largediameter reinforced concrete piles directly[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(12): 2566-2574. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201312025.htm

[6] 弓永军. 磨料水射流切割技术研究现状及其发展趋势[J]. 液压与气动, 2016(10): 1-5. https://www.cnki.com.cn/Article/CJFDTOTAL-YYYQ201610001.htm GONG Yong-jun. Research status and development trend of abrasive water jet cutting technology[J]. Hydraulic and Pneumatic, 2016(10): 1-5. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YYYQ201610001.htm

[7] HOOD M. Cutting strong rock with a drag bit assisted by high-pressure water jets[J]. Africa Institute Mining Metal, 1976, 177(4): 43-54.

[8] 神山守. 地下建設における2液混合噴流の地盤掘削特性および地中支障物の切削性に関する研究[D]. 东京: 日本早稲田大学, 2018. KAMIYAMA MAMORU. Study on the Characteristics of Dual-Fluid Jets for the Soil Excavation and the Obstacles Cutting in Underground Construction[D]. Tokyo: Akita University, 2018. (in Japanese)

[9] 卢义玉, 连红军, 卢建中. 水射流辅助刀具破碎岩石机理及射流位置的研究[J]. 矿山机械, 2005, 33(11): 6-8. https://www.cnki.com.cn/Article/CJFDTOTAL-KSJX200511000.htm LU Yi-jun, LIAN Hong-jun, LU Jian-zhong. Study on the mechanism of rock breaking and the position of water jet assisted cutter[J]. Mining Machinery, 2005, 33(11): 6-8. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-KSJX200511000.htm

[10] 卢义玉, 陆朝晖, 李晓红, 等. 水射流辅助PDC刀具切割岩石的力学分析[J]. 岩土力学, 2008, 29(11): 3037-3040. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX200811030.htm LU Yi-jun, LU Zhao-hui, LI Xiao-hong, et al. Mechanical analysis of water jets assisting PDC bit to cut rocks[J]. Rock and Soil Mechanics, 2008, 29(11): 3037-3040. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX200811030.htm

[11] 张文华, 汪志明, 于军泉, 等. 高压水射流-机械齿联合破岩数值模拟研究[J]. 岩石力学与工程学报, 2005, 24(23): 4373-4382. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200523031.htm WANG Fei, YUAN Da-jun, DONG Chao-wen, et al. Numerical simulation for combined breaking rock with high pressure water jet and mechanical bit[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(23): 4373-4382. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200523031.htm

[12] 曾锐. 滚筒式采煤机-高压水射流联合截割系统的设计与研究[D]. 徐州: 中国矿业大学, 2018. ZENG Rui. Design and Research on Combined Cutting System of Drum Shearer & High Pressure Water Jet[D]. Xuzhou: China Mining University, 2018. (in Chinese)

[13] 陈跃强. 磨料水射流-截齿联合破岩性能研究[D]. 徐州: 中国矿业大学, 2018. CHEN Yue-qiang. Research on Rock Breaking Performance of Pick Assisted with Abrasive Water Jet[D]. Xuzhou: China Mining University, 2018. (in Chinese)

[14] 杨清文, 王晓敏. 前混合磨料水射流切割钢板和混凝土的实验研究[J]. 兵工学报, 2005, 26(1): 133-135. https://www.cnki.com.cn/Article/CJFDTOTAL-BIGO200501031.htm YANG Wen-qing, WANG Xiao-min. Experimental study on cutting steel plate and concrete with premixed abrasive water jet[J]. Acta Armamentarii, 2005, 26(1): 133-135. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BIGO200501031.htm

[15] 王伟. 高压磨料水射流切割碳纤维复合材料的试验研究[D]. 哈尔滨: 哈尔滨理工大学, 2015. WANG Wei. Study on the Experiment of Carbon Fiber Composite Materials with High-Pressure Abrasive Water Jet Cutting[D]. Harbin: Harbin Institute of Ice Technology, 2015. (in Chinese)

[16] 赵宏伟. 磨料水射流切割微晶复合材料的试验研究[D]. 哈尔滨: 哈尔滨理工大学, 2017. ZHAO Hong-wei. Study on the Experiment of Microcrystalline Composite Materials with Abrasive Water Jet Cutting[D]. Harbin: Harbin Institute of Ice Technology, 2017. (in Chinese)

[17] 王哲, 吴淑伟, 姚王晶, 等. 盾构穿越既有桥梁桩基磨桩技术的研究[J]. 岩土工程学报, 2020, 42(1): 117-125. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202001019.htm WANG Zhe, WU Shu-wei, YAO Wang-jing. Grinding pile technology of shield tunnels crosssing pile foundation of existing bridges[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(1): 117-125. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202001019.htm

[18] 张文超, 武美萍, 任仲贺. 基于LS-DYNA仿真的射流加工参数分析[J]. 表面技术, 2017, 46(10): 268-276. https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201710042.htm ZHANG Wen-chao, WU Mei-ping, REN Zhong-he. Analysis of jet flow machining parameters based on LS-DYNA simulation[J]. Surface Technology, 2017, 46(10): 268-276. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201710042.htm

-

期刊类型引用(11)

1. 王德福. 盾构滚刀切削桩基相互作用机理及关键参数分析研究——以海珠湾盾构隧道为例. 现代隧道技术. 2024(01): 216-228 .  百度学术

百度学术

2. 王仕会,刘道生,邹彬. 盾构机推进液压系统的改进. 机床与液压. 2024(20): 136-141 .  百度学术

百度学术

3. 欧阳剑,段锴,曾庆成,沈翔,黄书华,田兆平. 盾构滚刀-切刀组合切削桩基相互作用机理及关键参数分析研究. 土木工程学报. 2024(S1): 102-108 .  百度学术

百度学术

4. 张金良,罗星臣,杨风威,傅杰,夏毅敏,罗南川. 磨料水射流辅助与常规工况下滚刀破岩特性对比研究. 振动与冲击. 2023(12): 333-340 .  百度学术

百度学术

5. 杨晨光,李彧,弥海晨,邹珦洋. 高压水射流技术在道路工程中的应用现状及展望. 现代交通技术. 2023(05): 25-30 .  百度学术

百度学术

6. 潘超,王泽峰,蒋宇涛,钟金文. 基于三维扫描的水射流冲击下再生混凝土断面形貌特征分析. 振动与冲击. 2023(22): 193-203 .  百度学术

百度学术

7. 张宁,黄新杰,王川,徐彬,张建成,张波. 高压水射流切割混凝土试验与数值模拟. 隧道与地下工程灾害防治. 2023(04): 47-56+92 .  百度学术

百度学术

8. 周新超,马小晶,廖翔云,齐思维,李宏煜. 磨料水射流冲击孔隙岩体的SPH模拟研究. 岩土工程学报. 2022(04): 731-739 .  本站查看

本站查看

9. 黄毅,刘正好,马险峰,朱瑶宏,董子博. 机械法联络通道管片切削试验与数值模拟研究. 隧道建设(中英文). 2022(S1): 93-103 .  百度学术

百度学术

10. 吴志强,李瑞红,陈城,李忠艳. 高压水射流清障施工盾构掘进面稳定性研究. 人民长江. 2022(09): 127-133 .  百度学术

百度学术

11. 曹文正,余家乐,李尧. 磨料射流切割桩基钢筋性能试验研究. 隧道建设(中英文). 2021(09): 1509-1515 .  百度学术

百度学术

其他类型引用(6)

下载:

下载: