Prevention and control technology of rock burst in deep stope with complex solid boundary

-

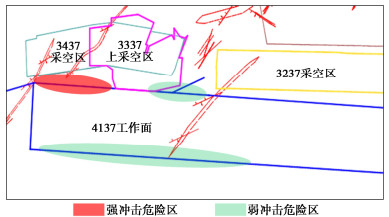

摘要: 深部复杂立体边界采场在采掘期间很容易发生冲击地压,若采场再留有宽度较大的不规则阶段煤柱,则采场的冲击地压危险性更高。以侧向留设不等宽煤柱、回风顺槽上侧为立体不规则开采边界的赵各庄煤矿4137工作面为研究背景,建立了采场顶板结构力学模型,进行了冲击地压成因分析;在基于耗散结构体的耗散机制研究基础上,针对4137工作面煤层赋存条件,提出了以“L”、“I”型耗散结构体为主导的冲击地压防控技术;通过在不等宽煤柱区域实施“L”型耗散结构体,调整回采巷道煤岩体侧向集中高应力分布、改变了煤层能量耗散模式;通过在工作面实施“I”型弱结构体,在采场超前区域制造出一个动态移动的耗散结构释能体,该耗散结构体扩大了应力场范围、降低了应力集中程度、改变了煤体冲击能量聚集模式;煤层注水使采场煤体得到充分弱化,强化了耗散结构体的防冲功能。该防控技术在4137工作面进行了现场试验,试验显示冲击地压得到有效控制。Abstract: Rock burst is easy to occur in deep stope with complex soild boundary during excavation. If the irregular coal pillar with a larger width is left in the stope, the risk of rock burst in the stope will be stronger. Taking the working face No. 4137 of Zhaogezhuang coal mine with coal pillars with an unequal width at lateral side and a solid and irregular upper side of return air chute mining boundary as the research background, a mechanical model for the roof structures of the stope is established, and the causes for rock burst are analyzed. Based on the researches on the dissipative mechanism of dissipative structure body, according to the occurrence conditions of coal seam in the working face No. 4137, the prevention and control technology of rock burst dominated by L-and I-type dissipative structures is proposed. Through the implementation of L type dissipative structure in the area of coal pillars with an unequal width, the lateral concentrated high stress distribution of coal and rock mass in mining roadway is adjusted, and the energy dissipation mode of coal seam is changed. Through the implementation of I-type weak structure body in the working face, a dynamic moving dissipative structure energy release body is produced in the leading area of the stope. The dissipative structure body expands the range of stress field, reduces the stress concentration degree, and changes the accumulation mode of coal impact energy. The water injection in coal seam weakens the coal body and strengthens the anti-scour function of dissipative structures. The prevention and control technology is tested in the working face No. 4137, and the rock burst is effectively controlled.

-

0. 引言

冲击地压是煤矿最严重的动力灾害之一[1-4]。中国一些老矿井和深部开采矿井由于开采历史久远、地质条件复杂多变、地应力较高,导致部分采场往往存在边界的复杂性,特别是地质因素导致的留设煤柱的不规则性。深部冲击煤层采场边界的复杂性导致了冲击地压成因、显现特征的差异性,其中,不规则煤柱型冲击地压是深部矿井的主要冲击类型之一,立体不规则、不等宽煤柱的存在是部分冲击地压矿井发生严重冲击地压灾害的主要原因[5]。大量学者对该类冲击地压发生机理、预测与防控技术进行了深入的研究[6-10]。一些学者针对深部开采不规则煤柱条件下采场的冲击地压机理、防范措施等进行了研究,杨伟利等[11]运用理论分析和数值模拟分析了采场遗留煤柱的垂直应力分布规律和特征,就开采前后残留煤柱阻抗力、冲击力的相互关系进行了对比分析,用以指导判断冲击危险性的强弱程度;曹正正等[12]将煤柱板裂结构视为耗能体,将巷道顶板视为释能体,建立了由释能体和耗能体组成的耦合系统力学模型,通过分析耦合系统的能量平衡关系,揭示分析了基于折迭突变力学模型的煤柱动力失稳机理,为煤柱型冲击地压的机理分析提供了新思路;宋义敏等[13]通过具体工程的综合分析,建立了煤柱失稳滑动型和裂隙失稳扩展型两种破坏类型,并分析了煤柱变形场的分布特征,以此研究了煤柱弱面失稳滑动型、裂隙失稳扩展型破坏的主要原因;张明等[14]分析了具体采场煤柱上部支承压力的分布规律、煤柱力学稳定性后,就煤柱的整体力学失稳问题,基于力学分析,提出了P-Rc判据,为煤柱失稳分析提供了一条新的方法。针对深部不规则煤柱的冲击地压问题,虽然诸多学者对不同条件的采场进行了相关研究[15-18],但针对深部开采、边界复杂、存在不等宽煤柱的采场冲击地压发生机理,特别是控制技术的相关系统性研究相对较少。

本文以赵各庄矿4137工作面为研究背景,针对采场的边界不规则煤柱赋存特性,通过对采场巷道布置及采掘时空关系的静动态分析,分析确定了冲击地压发生的主导影响因素;通过建立采场煤岩层结构力学模型,并进行相关力学分析研究,揭示了深部立体复杂边界采场冲击地压发生机理;针对具体采场地质开采条件,构建了基于煤岩耗散结构体的冲击地压防控力学模型,分析了立体、不等宽煤柱应力分布、能量演化规律,提出了针对不等宽煤柱的“L”形耗散结构体和针对采场的“I”形耗散结构体的冲击地压防控技术,并进行现场试验。

1. 研究背景

赵各庄矿进入12水平(埋深1054 m)开采后,在井口西翼宽缓向斜区域出现明显的冲击地压现象,特别是在采掘期间,其采场超前巷道出现明显的冲击地压显现。冲击地压显现表现为巷道两帮煤体出现不同程度的震动与声响、有时伴随有大量煤尘、巷道断面瞬间发生较严重收缩变形、顶底板位移量急剧增大、巷道底鼓严重等现象。

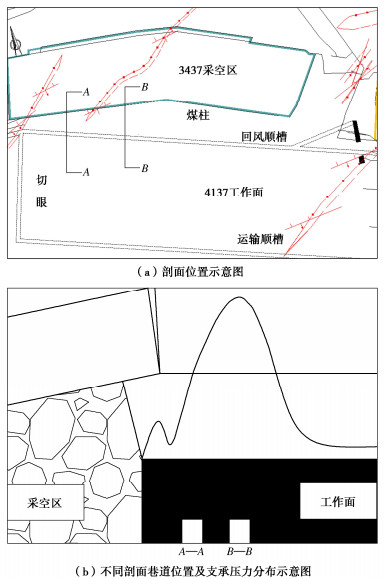

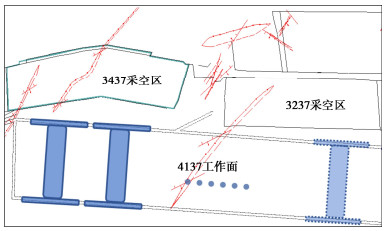

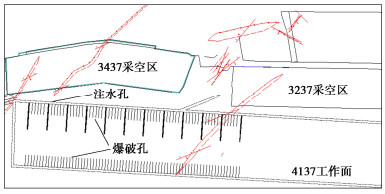

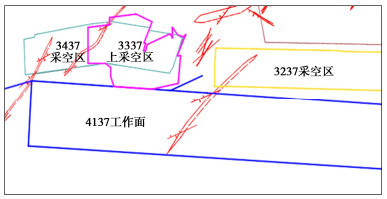

赵各庄4137工作面开采12#煤层。该工作面位于14水平西翼1石门,上至3237、3437、3337工作面的采空区,已回采完毕;下至14水平(无采掘工程);东至14西1石门,1石门以东无采掘工程;西至14西3石门剖面线以东9 m,剖面线以西无采掘工程。图 1是4137工作面平面示意图。

工作面采深1100~1250 m,工作面煤层均厚为9.6 m,倾角平均为29°,属于倾斜厚煤层[19],#12煤层具有冲击倾向性;煤层顶板为1.2 m厚的黏土岩、3.6 m厚的粉砂岩及1.05~5.0 m厚的砂岩互层等,底板为1.5 m厚的粉砂岩和2.75 m厚的细砂岩等;4137工作面采用综采放顶煤开采工艺,采放比为1︰3(采高为2.4 m,顶煤平均厚度7.2 m),工作面倾斜长度为110 m,工作面走向长度为1200 m。

2. 冲击地压主导因素分析

2.1 地质因素分析

(1)开采深度大

4137工作面采深达1250 m,远远超过了赵各庄矿井口区域(构造带)发生冲击地压的临界深度,属于超深度采场,原始地应力高。

(2)煤体冲击倾向性高

#12煤层煤体的硬度系数平均为1.8,煤体含水率普遍低小于3%,鉴定结果为强冲击倾向性。

(3)顶底板强度高

#12煤层顶底板以粉砂岩、细砂岩为主,硬度系数为8-11,具有冲击倾向性。

(4)地质构造复杂

4137工作面处于地质异常区域,采掘过程中揭露断层多条,周围采场采掘时伴有冲击显现,且断层、褶曲附近冲击显现尤为明显。

2.2 开采因素分析

(1)复杂立体边界

4137工作面回风顺槽左边界为已开采完毕的3337顶分层工作面、3437底分层工作面。3337工作面边界不规整、采场形状不规则;3437工作面为综放面,包括原生、网下综放2段;3337工作面与3237工作面之间因断层原因留设了大煤柱;3397东下面已回采,4137工作面在该区域为保护层下开采。

纵观4137工作面回风顺槽左边界的开采条件,其边界为立体不规则形状,具有开采厚度差异性大(岩层冒落高度不同)、边界不整齐(多边形煤柱)的复杂立体型边界特征。

(2)不等宽煤柱

4137工作面与3437工作面采空区之间存在不等宽煤柱,煤柱从切眼向外逐渐增大,煤柱最窄处宽度为8 m,最宽处为40 m;该区域的回风顺槽受不等宽煤柱高应力影响,采掘期间容易诱发冲击地压。

(3)采空侧向煤柱高应力

4137工作面上边界为3437工作面、3237工作面采空区,受采空区侧向高应力影响,4137工作面采掘期间具有冲击危险性。

(4)工作面超前和侧向支承压力

工作面回采后,会在超前顺槽和侧向一定范围内形成超前、侧向支承压力[20-21],超前支承压力、侧向支承应力和侧向煤柱高应力叠加,煤柱内应力集中程度高的区域具有冲击危险性。

2.3 冲击地压主导因素分析

通过对4137工作面冲击地压影响因素的分析,工作面冲击地压主导因素如下:

(1)不等宽煤柱是本工作面特别是回风顺槽冲击危险的第一主导因素。

8~40 m不等宽煤柱、侧向采场边界复杂性使得沿空顺槽处于采空边缘高应力影响范围内,且不同区段顺槽的应力分布具有明显的差异性。

(2)具有3硬条件(顶底板坚硬,煤层相对较硬)的工作面应力集中程度高、煤岩体能量积聚程度高,且煤层及顶底板均具有冲击倾向性是工作面冲击危险的另一主导因素,从而增大了工作面冲击地压危险性。

(3)超深度与断层是工作面冲击危险的基本主导因素。

1250 m的埋深使得工作面的原始地应力高,断层造成构造应力高,是工作面冲击危险性的基本影响因素。

3. 复杂立体边界采场冲击地压成因

3.1 不等宽煤柱的“空间效应”

在不同宽度煤柱内掘进巷道,巷道围岩应力的大小及发生冲击地压的可能性具有重大差异。工作面开采前,作用在煤柱上的应力分布可视为处于相对静态,巷道的空间位置不同,其冲击危险性具有重大差异,呈现出巷道冲击危险性随煤柱宽度变化的“空间效应”。

图 2(a)为工作面及煤柱区域的俯视图,2(b)为不同煤柱宽度处(A—A剖面、B—B剖面)采空侧压分布示意图。

采空侧向应力场包括低应力区(由裂断岩层重力作用下的“内应力场”和塑性破坏区内应力小于原始应力的一部分构成)、高应力区(包括弹塑性区中应力超过原始应力的部分)及原始应力区等3个部分。

4137工作面回风顺槽侧为不等宽煤柱,煤柱宽度为8~40 m。由图 2(a)可知,不等宽煤柱区段内的回风顺槽均位于采空侧压高应力影响范围之内;由图 2(b)A—A、B—B剖面综合分析可知,不同区段的回风顺槽所受的采空侧压影响不同,即顺槽上部所受采空侧向压力的集中度不同,造成其冲击地压危险性在空间上的不同。

3.2 不等宽煤柱的“时间效应”

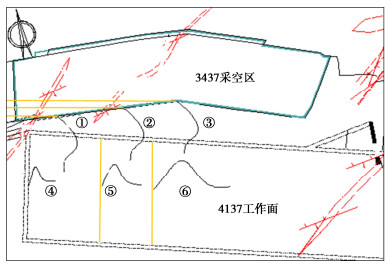

采场开采后,超前回风顺槽围岩受到侧向应力与超前开采应力的叠加作用,如图 3所示,4137工作面回风顺槽围岩上的实际应力集中系数k叠为

k叠=ak侧+bk前, (1) 式中,k叠为开采后回风顺槽围岩上叠加的实际应力集中系数,k侧为已采工作面的采空侧压在回风顺槽围岩上形成的支承压力集中系数,k前为工作面超前顺槽的围岩上形成的应力集中系数,a,b为与采场有关的调控系数。

回风顺槽在不等宽煤柱中的位置不同,因而侧向应力集中系数k侧不同(如图 3中的①、②、③所示);随着4137工作面的推采,工作面超前支承压力峰值位置和影响范围逐渐前移(如图 3中的④、⑤、⑥所示),应力集中系数k前逐渐增大;侧向和超前支承压力在回风顺槽围岩上的叠加在不同区段将出现不同的应力集中。采空侧压与超前支承压力在回风顺槽不同区段和不同回采时间上叠加影响的不同造成了其冲击危险性在时间上的重大差异。k叠的大小与采场推进速度有密切关系,呈现出不等宽煤柱与巷道冲击危险性的“时间效应”。

3.3 冲击地压成因分析

(1)回风顺槽冲击地压成因分析

回风顺槽处于复杂立体开采边界,其危险性与开采边界密切相关。

由式(1)可知,上顺槽叠加应力与煤柱宽度有关,煤柱宽度直接影响着巷道围岩应力分布状态,巷道位于侧向高应力区域时,将承受高集中应力,巷道围岩积聚高弹性能,工作面开采时,会受到超前动态应力的叠加作用,故高原始地应力、侧向高静态应力与工作面超前高动态应力的叠加是沿空巷道发生冲击地压的主导原因。

图 4是回风与运输采掘期间冲击危险区域,受到上部工作面开采边界影响,回风顺槽冲击危险性集中在AB区,其主要成因是开采边界不规则造成巷道位于侧向高应力区;AB之间的区域属于顶分层开采后的保护区,处于低应力区,相对安全。

(2)运输顺槽与工作面冲击地压成因分析

运输顺槽主要受到高地应力和本工作面超前支承应力的叠加作用,煤层在高应力作用下发生弹性破坏导致冲击地压的发生。

工作面煤层在高地应力和超前支承压力叠加作用下,煤体积聚了高能量的弹性能,在割煤、放煤等工序扰动下容易诱发工作面冲击地压。

4. 基于工程耗散结构体的冲击地压防控技术

4.1 工程耗散结构体防控冲击地压的应力分析

不等宽煤柱条件下,巷道受到侧向与推进方向上的叠加应力作用。人为施工耗散结构体后,巷道围岩应力分布发生2种变化:①改变侧向应力的分布形态,将高应力向采空区侧转移;②改变工作面开采形成的超前和侧向应力的分布模式。

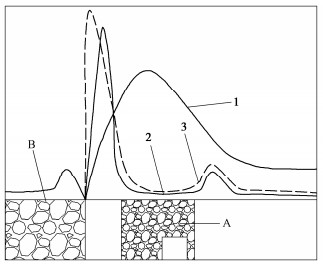

图 5是针对4137工作面具体煤层条件,建立的实施耗散结构前后的应力场变化模型,图 5中A为人工施工的耗散结构体(本文称为工程耗散结构体),B为采空区,曲线1为未实施耗散结构体前的应力分布,曲线2为实施耗散结构体后,工作面尚未开采的巷道围岩应力分布,曲线3为工作面开采后某时刻的应力分布曲线。

从实施耗散结构前后的应力分布形态可知,工程耗散结构体对静态与动态应力分布与大小起到“保护性”调整作用,巷道冲击危险性由巷道周边区域转移到远离巷道的采空区一侧,冲击危险性发生向远离巷道的方向“移位”。

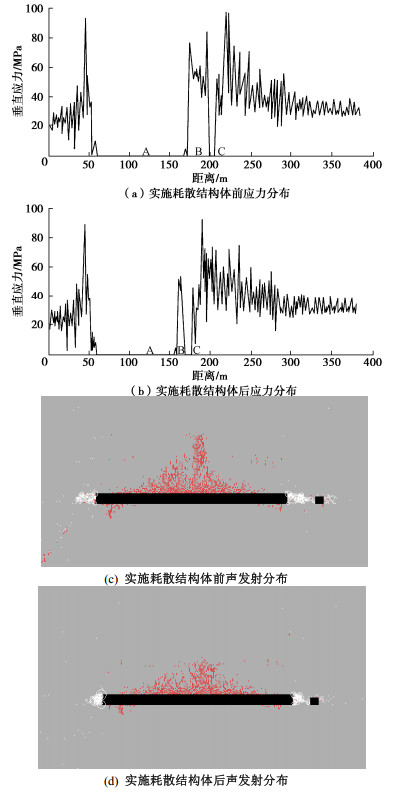

图 6(a)、(b)是根据赵各庄矿4137工作面煤层赋存条件、煤岩力学参数,采用RFPA软件模拟(图 2中BB剖面)的垂直应力分布曲线,A,B,C分别代表采空区、煤柱、巷道。图 6(c)、(d)是煤柱宽度分别为30,10 m的声发射分布图。

图 6的垂直应力分布特征表明,宽煤柱条件下,作用在煤柱上的应力出现集中现象,最高达到80 MPa,冲击危险性较高;实施工程耗散结构体后,应力分布发生明显改变,应力集中区向采空区侧转移,作用在煤柱上的应力明显降低,最高达到50 MPa,巷道冲击危险性大幅度降低。

由图 6可知,宽煤柱条件下,煤柱、巷道均会出现能量的释放,冲击危险性较高;实施工程耗散结构体后,由于改变了煤体原有冲击倾向性、降低了煤体强度,冲击能量集中在采空区侧,巷道围岩释放能量大幅度降低,显然巷道的冲击危险性大幅度降低。

4.2 工程耗散结构体防控冲击地压的煤岩刚度分析

(1)耗散结构体力学模型的建立

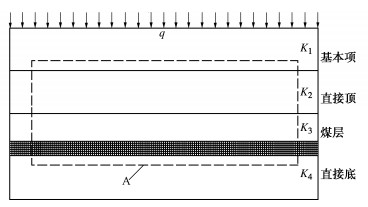

赵各庄矿4137工作面煤层、顶板和底板均可视为脆性体,将近场煤岩层视为脆性冲击体,建立图 7所示的煤层与顶底板结构力学模型。

K1,K2,K3,K4分别为基本顶、直接顶、煤层和直接底的刚度,q为作用在基本顶上的均布力。

(2)耗散结构体力学分析

在煤层未开采状态下,顶底板和煤层在原始应力场的作用下均储存一定的弹性应变能;煤层开采后,打破了围岩原有应力平衡,导致了应力重新分布,从而致使煤岩层发生压缩变形,积聚了变形能。从积聚应变能的角度分析,压缩量和煤岩层的刚度是决定应变能的主要参数。

根据煤岩层近场结构力学模型,煤岩层结构的整体有效刚度Ky表达式为

1Ky=1K1+1K2+1K3+1K4。 (2) K1,K4受开采影响小,假设开采前后基本不变,4137工作面顶底板为坚硬岩层,在未开采状态下,顶底板及煤层刚度都较大,容易积聚弹性能,冲击危险性高。

4137工作面煤层分层特性明显,假设煤层3个分层的刚度从上到下依次分别为K31,K32,K33,则煤层的有效刚度为

1K3=1K31+1K32+1K33。 (3) 将式(3)代式(2)中,可得放顶煤开采煤层及顶底板结构的整体有效刚度为

1Ky=1K1+1K2+1K31+1K32+1K33+1K4。 (4) 式(4)表明,煤岩层近场结构的整体刚度主要与煤层结构、顶底板强度有关,调整结构的整体刚度,需要改变直接顶、煤层的结构与变形特性。

(3)工程耗散结构体防冲原理

将近场煤岩层中刚度大、难变形、易积聚能量的冲击型结构体变为刚度小、易变形、易耗散能量的结构体是耗散结构体防控冲击地压的基本原理。

通过改变煤岩层近场结构模型中的K2,K3(力学模型中A部分),实现冲击地压的有效控制。

4137工作面为综放开采,煤层顶分层(K31)由于综放采高增大,顶煤超前发生变形破坏,K31明显减小;在底分层中制造耗散结构体后,K33的力学性质发生变化,在上分层变软、底分层破坏条件下,中分层强度在矿压与人为破坏下明显降低,K3大幅度减小,远远小于原始未开采状态下刚度。

因此,只要通过采取措施降低K33,就能达到降低K3的目的。同样,采取破坏直接顶措施,也实现降低K2的目的。假设实施有效措施后的煤层、顶底板刚度变为KH:

1KH=1K1+1K4+1K′31+1K′32+1K′33+1K′2, (5) 显然,KH < Ky。

经过实施上述措施后,在同样的顶板下沉量条件下,实施耗散结构体的煤层应力发生变化,且煤岩积聚的能量明显小于原始状态下积聚的能量。

以上分析表明:放顶煤开采和工作面实施耗散结构体能够大大降低采场的冲击地压危险。

5. 防控实践与效果检验

针对4137工作面开采边界、采场具体地质开采条件,设计了掘进与回采期间的冲击地压防控方案,并进行全方位的实施。

5.1 不等宽煤柱区域巷道掘进防控技术

不等宽煤柱区域冲击危险性高,在该区域内掘进巷道采用端头及后路循环爆破卸压措施。

如图 8所示的端头及后路循环爆破卸压俯视图可知:一组爆破包括7个爆破孔,其中端头布置3个爆破孔,两帮分别布置2个爆破孔;迎头钻孔布置在同平面内,其中一个布置在中间,其余两个布置在两侧,距中间钻孔各为1.0 m,中间钻孔垂直煤壁,两边钻孔斜向外30°布置;两帮钻孔距迎头5 m布置,两帮孔间距3 m;孔深度8.0 m,孔径Φ42 mm,钻孔斜向上3~5°,钻孔距离底板1.2m。

5.2 L型弱结构体防控技术

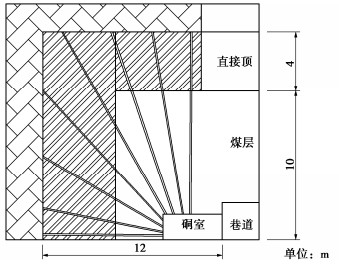

沿回风顺槽向老空侧实施硐室,硐室尺寸(长×宽×深)为3 m×2.5 m×6 m,对硐室进行临时支护,实施措施完毕后,对硐室进行回填。

在硐室内向煤层、顶板进行深孔爆破卸压,钻孔长度12~14 m,钻孔终点在纵向上成一垂直直线、在横向上成一水平线,其作用是切断顶板与煤层;钻孔直径42 mm,装药长度3.5 m,如图 9所示。

在回风顺槽距切眼40 m处开始向煤柱侧布置软弱空间,每隔30 m布置一个,布置到断层附近。图 10是硐室布置平面图,采取L型耗散结构体后,不等宽煤柱分割成介质属性不同的2个部分:耗散结构体与剩余煤柱体,在采动应力作用下,N区域煤体发生冲击破坏,而耗散结构体(M区域)由于采取了煤体的改性措施,将冲击煤层改变为无冲击煤层,并在巷道围岩制造出弱结构体,该弱结构体具有耗散功能,对回风顺槽起到缓冲、防护作用。

5.3 Ⅰ型弱结构体防控技术

根据#12煤层力学特征及不等宽煤柱工作面冲击地压的防控机理,在回风顺槽工作面侧煤体中进行高压注水和深孔爆破,煤柱侧进行深孔爆破卸压;在运输顺槽两侧煤层进行爆破卸压;工作面煤壁采用深孔爆破卸压。通过这一系列的措施后,在采场中制造出“Ⅰ”型能量耗散结构体。随着工作面的回采,每推进5 m,在工作面超前15 m内实施一个“Ⅰ”形耗散结构体,如图 11所示。

Ⅰ型耗散结构体改变了4137工作面超前顺槽、工作面煤岩体力学性质,大幅度降低了煤岩层冲击倾向性,Ⅰ型耗散结构体随工作面回采而动态前移,对采场冲击地压具有整体防控功能,对采场动态高应力冲击危险区域起到弱化、缓冲、防护作用。

Ⅰ型耗散结构体主要通过实施煤层注水和对煤层深孔爆破技术而形成。

煤层注水、爆破参数如下。

(1)煤层注水参数

在回风顺槽,沿煤层倾向下行布置钻孔,注水孔直径45 mm,孔深30 m,注水孔间距30 m,注水压力为8 MPa,封孔长度10 m。

(2)煤层深孔爆破钻孔布置参数

距离煤层底板1.0~1.2 m处打水平爆破钻孔,爆破孔为单排布置,孔径为42 mm,钻孔深度15~17 m,孔间距4~5 m。如图 12所示爆破钻孔布置示意图。

5.4 冲击地压防控效果

(1)应力法监测

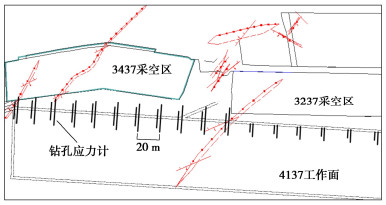

工作面回采期间在回风顺槽两帮进行了应力法监测,工作面从切眼前20 m开始,沿推采方向在回风顺槽两帮(18 m以下煤柱沿空侧帮部不布置)每隔20 m布置1组自主研发的主动承压式可定位钻孔应力计,深孔13 m、浅孔6 m,组内孔间距2 m,初始应力1.3 MPa,预警指标浅基点2.0 MPa、深基点2.5 MPa,进行工作面回采期间应力变化监测。应力计布置如图 13所示。

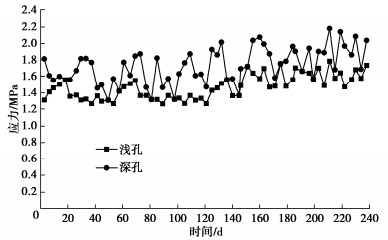

如图 14所示的典型钻孔监测应力-时间曲线可知:工作面回采期间实施耗散结构体后应力监测值均未超过预警值,耗散结构体对冲击地压的防控效果显著,工作面冲击地压得到有效控制。

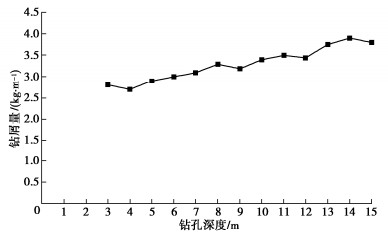

(2)钻屑法监测

工作面回采期间在两顺槽两帮(15 m以下煤柱沿空侧帮部不实施)进行了钻屑法监测,钻孔孔径42 mm,钻孔深度15 m,预警指标为4.2 kg/m。如图 15所示的典型钻孔钻屑量-钻孔深度曲线可知:工作面回采期间实施耗散结构体后钻屑量均未超过预警值,最大为3.9 kg/m,卸压效果显著。

6. 结论

(1)分析了4137工作面冲击地压影响因素和主导因素,通过对不等宽煤柱的“空间效应”和工作面开采的“时间效应”的分析,揭示了立体边界复杂、不等宽煤柱采场冲击地压机理;工作面回采前,不同区段的回风顺槽所受的采空侧压影响不同;工作面回采后,高地应力、采空侧压与超前支承压力在回风顺槽围岩发生叠加,造成超前巷道的冲击危险性在不同区域、不同时间上出现重大差异。

(2)针对4137工作面地质开采条件,建立了耗散结构体防控冲击地压力学模型,从应力分布、能量演化两方面分析了工程耗散结构体防控冲击地压的力学原理。

(3)针对4137工作面地质开采条件,设计和实施了针对不等宽煤柱的“L”形耗散结构体和针对采场的“I”形耗散结构体为核心的冲击地压防控技术方案,并实施了“L”形和“I”形耗散结构体,经应力法和钻屑法的冲击地压卸压效果检验表明,防冲效果明显,实现了工作面冲击地压的整体防控和安全回采。

-

-

[1] 潘立友, 侯家骏, 薄树祥. 悬顶结构下软底板采场冲击地压成因与防控研究[J]. 中国煤炭, 2017, 43(12): 72–75, 114. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGME201712016.htm PAN Li-you, HOU Jia-jun, BO Shu-xiang. Study on causes and prevention measures of rock burst in soft floor under suspended roof structure[J]. China Coal, 2017, 43(12): 72–75, 114. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGME201712016.htm

[2] WANG G F, JIN F, GONG S Y, et al. Generating behaviors of strong tremors and experimental study of rockburst-triggering criterion[J]. Shock and Vibration, 2019, 6319612.

[3] 齐庆新, 欧阳振华, 赵善坤, 等. 我国冲击地压矿井类型及防治方法研究[J]. 煤炭科学技术, 2014, 42(10): 1–5. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201410001.htm QI Qing-xin, OUYANG Zhen-hua, ZHAO Shan-kun, et al. Study on types of rock burst mine and prevention methods in China[J]. Coal Science and Technology, 2014, 42(10): 1–5. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201410001.htm

[4] 姜耀东, 潘一山, 姜福兴, 等. 我国煤炭开采中的冲击地压机理和防治[J]. 煤炭学报, 2014, 39(2): 205–213. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201402001.htm JIANG Yao-dong, PAN Yi-shan, JIANG Fu-xing, et al. State of the art review on mechanism and prevention of coal bumps in China[J]. Journal of China Coal Society, 2014, 39(2): 205–213. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201402001.htm

[5] 姜福兴, 刘懿, 翟明华, 等. 基于应力与围岩分类的冲击地压危险性评价研究[J]. 岩石力学与工程学报, 2017, 36(5): 1041–1052. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201705001.htm JIANG Fu-xing, LIU Yi, ZHAI Ming-hua, et al. Evaluation of rock burst hazard based on the classification of stress and surrounding rock[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(5): 1041–1052. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201705001.htm

[6] 潘立友, 张立俊, 刘先贵. 冲击地压预测与防治实用技术[M]. 徐州: 中国矿业大学出版社, 2006. PAN Li-you, ZHANG Li-jun, LIU Xian-gui. Practical Technology of Rock Burst Prediction and Prevention[M]. Xuzhou: China University of Mining and Technology Press, 2006. (in Chinese)

[7] 潘一山, 李忠华, 章梦涛. 我国冲击地压分布、类型、机理及防治研究[J]. 岩石力学与工程学报, 2003, 22(11): 1844–1851. doi: 10.3321/j.issn:1000-6915.2003.11.019 PAN Yi-shan, LI Zhong-hua, ZHANG Meng-tao. Distribution, type, mechanism and prevention of rockbrust in China[J]. Chinese Journal of Rock Mechanics and Engineering, 2003, 22(11): 1844–1851. (in Chinese) doi: 10.3321/j.issn:1000-6915.2003.11.019

[8] 窦林名, 何学秋. 煤矿冲击矿压的分级预测研究[J]. 中国矿业大学学报, 2007, 36(6): 717–722. doi: 10.3321/j.issn:1000-1964.2007.06.001 DOU Lin-ming, HE Xue-qiu. Technique of classification forecasting rock burst in coal mines[J]. Journal of China University of Mining & Technology, 2007, 36(6): 717–722. (in Chinese) doi: 10.3321/j.issn:1000-1964.2007.06.001

[9] 潘俊锋, 毛德兵, 蓝航, 等. 我国煤矿冲击地压防治技术研究现状及展望[J]. 煤炭科学技术, 2013, 41(6): 21–25, 41. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201306005.htm PAN Jun-feng, MAO De-bing, LAN Hang, et al. Study status and prospects of mine pressure bumping control technology in China[J]. Coal Science and Technology, 2013, 41(6): 21–25, 41. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201306005.htm

[10] 李振雷, 何学秋, 窦林名. 综放覆岩破断诱发冲击地压的防治方法与实践[J]. 中国矿业大学学报, 2018, 47(1): 162–171. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201801021.htm LI Zhen-lei, HE Xue-qiu, DOU Lin-ming. Control measures and practice for rock burst induced by overburden fracture in top-coal caving mining[J]. Journal of China University of Mining & Technology, 2018, 47(1): 162–171. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD201801021.htm

[11] 杨伟利, 姜福兴, 温经林, 等. 遗留煤柱诱发冲击地压机理及其防治技术研究[J]. 采矿与安全工程学报, 2014, 31(6): 876–880, 887. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201406008.htm YANG Wei-li, JIANG Fu-xing, WEN Jing-lin, et al. Study on mechanisms of rock burst induced by a left coal pillar and prevention technology[J]. Journal of Mining and Safety Engineering, 2014, 31(6): 876–880, 887. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201406008.htm

[12] 曹正正. 巷式充填开采煤柱失稳机制及冲击矿压机理研究[D]. 徐州: 中国矿业大学, 2017. CAO Zheng-zheng. Research on Mechanism of Coal Pillar Instability and Rockburst in Roadway Backfilling Mining Technology[D]. Xuzhou: China University of Mining and Technology, 2017. (in Chinese)

[13] 宋义敏, 杨小彬. 煤柱失稳破坏的变形场及能量演化试验研究[J]. 采矿与安全工程学报, 2013, 30(6): 822–827. https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201306006.htm SONG Yi-min, YANG Xiao-bin. Evolution characteristics of deformation and energy fields during coal pillar instability[J]. Journal of Mining & Safety Engineering, 2013, 30(6): 822–827. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201306006.htm

[14] 张明, 姜福兴, 李家卓, 等. 基于巨厚岩层-煤柱协同变形的煤柱稳定性[J]. 岩土力学, 2018, 39(2): 705–714. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201802040.htm ZHANG Ming, JIANG Fu-xing, LI Jia-zhuo, et al. Stability of coal pillar on the basis of the co-deformation of thick rock strata and coal pillar[J]. Rock and Soil Mechanics, 2018, 39(2): 705–714. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201802040.htm

[15] 陈建强, 闫瑞兵, 刘昆轮. 乌鲁木齐矿区冲击地压危险性评价方法研究[J]. 煤炭科学技术, 2018, 46(10): 22–29. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201810004.htm CHEN Jian-qiang, YAN Rui-bing, LIU Kun-lun. Study on evaluation method of rock burst danger in Urumqi Mining Area[J]. Coal Science and Technology, 2018, 46(10): 22–29. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201810004.htm

[16] 周澎. 特厚煤层综放开采冲击地压防治技术与实践[J]. 煤炭科学技术, 2011, 39(4): 35–39. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201104009.htm ZHOU Peng. Technology and practices on mine pressure bumping prevention and control of fully mechanized top coal caving mining in ultra thick seam[J]. Coal Science and Technology, 2011, 39(4): 35–39. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201104009.htm

[17] 张月征, 纪洪广, 彭华, 等. 冲击地压与区域构造应力环境相关性及其应变响应特征[J]. 煤炭学报, 2016, 41(增刊2): 311–318. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2016S2005.htm ZHANG Yue-zheng, JI Hong-guang, PENG Hua, et al. Correlation between rockburst and regional tectonic stress environment and its strain response characteristics[J]. Journal of China Coal Society, 2016, 41(S2): 311–318. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2016S2005.htm

[18] 张基伟, 王金安. 大倾角特厚煤层悬顶结构能量分布特征与防冲方法[J]. 煤炭学报, 2014, 39(增刊2): 316–324. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2014S2005.htm ZHANG Ji-wei, WANG Ji-nan. Energy distribution characteristics and rock burst control methods of steeper inclined thick coal seam hanging roof[J]. Journal of China Coal Society, 2014, 39(S2): 316–324. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2014S2005.htm

[19] 姜福兴, 王平, 冯增强, 等. 复合型厚煤层"震-冲"型动力灾害机理、预测与控制[J]. 煤炭学报, 2009, 34(12): 1605–1609. doi: 10.3321/j.issn:0253-9993.2009.12.004 JIANG Fu-xing, WANG Ping, FENG Zeng-qiang, et al. Mechanism, prediction and control of "rock burst induced by shock bump" kind dynamic accident in composite thickness coal[J]. Journal of China Coal Society, 2009, 34(12): 1605–1609. (in Chinese) doi: 10.3321/j.issn:0253-9993.2009.12.004

[20] SONG D Z, WANG E Y, LI Z H, et al. Energy dissipation of coal and rock during damage and failure process based on EMR[J]. International Journal of Mining Science and Technology, 2015, 25(5): 787–795.

[21] SONG D Z, WANG E Y, LI N, et al. Rock burst prevention based on dissipative structure theory[J]. International Journal of Mining Science and Technology, 2012, 22(2): 159–163.

-

期刊类型引用(7)

1. 王文杰,陈理强,董文卓,孙铄寒. 三角煤柱孤岛工作面冲击地压防治技术研究. 煤炭技术. 2025(01): 78-82 .  百度学术

百度学术

2. 谭毅,张少普,何满潮,郭文兵,丁国利,王宇,程浩,李辉. 巨厚砂岩下采动覆岩裂隙场及微震时空演化规律研究. 矿业科学学报. 2025(01): 70-85 .  百度学术

百度学术

3. 曹安业,王常彬,杨旭,王冰,张宁,赵卫卫. 微震定位精度影响下采场裂隙表征与冲击地压预警. 煤炭科学技术. 2024(02): 1-9 .  百度学术

百度学术

4. 董文卓,陈理强,王文杰,史明伟,徐维正,马宏军. 上覆不规则煤柱孤岛工作面冲击地压弱结构法防治技术. 矿业安全与环保. 2024(02): 40-45+52 .  百度学术

百度学术

5. 张锋刚. 某矿3_2煤层瓦斯异常区预测模型的建立与应用. 采矿技术. 2024(05): 145-149 .  百度学术

百度学术

6. 徐维正,许斌,唐鹏,史明伟,董文卓,张沿. 空间煤柱影响下冲击地压防治技术研究. 煤炭工程. 2023(10): 85-91 .  百度学术

百度学术

7. 刘洋,陆菜平,王华,郭英,肖自义,夏磊,王超. 不规则煤柱变形破坏机理矩张量反演研究. 采矿与安全工程学报. 2023(06): 1201-1209 .  百度学术

百度学术

其他类型引用(6)

下载:

下载: